-

Shop Fabric

- Shop Soft Furnishings

- New Fabric

- Clearance Fabric

- Pound Fabrics

The Martindale rub score is a measurement taken to determine the durability of fabric in terms of wear and tear, and helps you to make an informed buying decision when shopping for fabric. It’s mainly used to find out whether a material is suitable for upholstery use in specific environments.

The main rule of thumb is simple–the higher the score, the more durable the fabric. Depending on your end use you might want to make sure that your fabric of choice meets certain minimum criteria.

A fabric that scores less than 10,000 rubs is considered suitable for decorative or non-upholstery use only. This can include cushions, throws, curtains and blinds.

If a score isn’t listed for a fabric, then it’s always a good policy to assume that it scores less than 10,000 until you know otherwise. In reality it might just mean that we’re waiting for results to come back, or even that we haven’t updated the website yet, but it can also mean that we’re certain that it won’t be suitable for any kind of upholstery use.

Fabric scoring between 10,000 and 15,000 rubs is suitable for light domestic upholstery. Ornamental furniture, or bedroom armchairs, would fall under this category, as will dining-room chairs.

A score between 15,000 and 25,000 means that a fabric will be suitable for general domestic upholstery. This covers most applications in a domestic setting, including sofas and armchairs that are subject to daily and repeated use.

Fabric in the general domestic band might not be suitable in upholstery that puts particularly high stress on the fabric–here we need fabric that’s suitable for heavy domestic use. Think here about reclining furniture, where the fabric rubs against itself every time the chair is put into its reclining position and back again.

Fabric in this band might also be considered suitable for light contract use. More detailed information on contract environments can be found further in this article.

We say that a fabric that has at least 30,000 rubs is suitable for general contract upholstery. This band covers the overwhelming majority of contract use-cases, but for upholstery placed under particularly heavy stress, you might want a fabric that even more durable still.

For particularly heavy-duty furniture you may want to source a fabric within the severe contract upholstery band.

A contract environment, plain and simply, is one that’s outside of a domestic setting. This will include offices, shops, hotels, restaurants, bars, pubs, clubs, schools and hospitals. There’s a very good reason to treat these environments differently than we do our own homes–these are high-traffic areas, in which upholstered furniture is subject to far more wear and tear.

Anyone working on contract projects might also need to be familiar with the rules surrounding the use of fire retardant fabric.

When shopping for fabric you might come across scores of over 40,000 – some even as high as 100,000 or more. Our policy at Fabric Online is that scores above 40,000 make no real-world difference to the longevity of upholstered furniture. This is true in the overwhelming majority of cases.

When we send our own fabric off for testing, we ask the laboratory to test only up to 50,000 rubs. It’s true that some fabrics here on our website list scores higher still, but in these cases the tests were carried out by our manufacturers and suppliers.

Based on the Martindale rub score, you can determine the most suitable fabric for your specific needs, whether you’re furnishing a home or a commercial space. Here’s a quick guide to help you choose the right fabric based on Martindale test scores.

These guidelines help in selecting the appropriate fabric based on its durability rating for different types of furniture and use.

To maximise the lifespan of your fabrics, it’s essential to follow these maintenance and care tips:

By shopping with us at Fabric Online, you can take advantage of competitive pricing and discounted items, making your fabric purchases from us a cost-effective option. We stock a wide range of high-quality fabrics such as upholstery fabric, fire retardant fabric, dress-making fabric, and much more.

Not only this, our secure and easy checkout process is simple, and our knowledgeable customer service team is ready to assist you with any questions about fabric care or recommendations based on your project requirements. You can find our contact details below.

Award Winning Service

Award Winning Service

Customers who shop at Fabric Online benefit from our award winning and trusted customer service–every time.

Free Sample Swatches

Free Sample Swatches

Shop with absolute confidence by taking advantage of our free sample service for all fabrics and furnishings.

Free Delivery Over £150

Free Delivery Over £150

Save even more with free Mainland UK delivery on orders over £150. Conditions and restrictions may apply.

Our Story

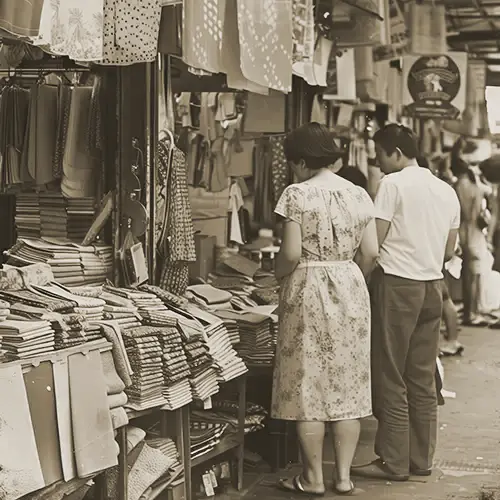

Our Story

From humble marketplace beginnings in Manchester to a nationwide online retailer and international wholesaler.

Trade Orders

Trade Orders

Trade customers looking to order larger or regular amounts of fabric should contact our dedicated wholesale team.

Clearance Fabric

Clearance Fabric

Unmissable, time-limited bargains on clearance and one-off fabrics, with up to 90% off RRP.