-

Shop Fabric

- Shop Soft Furnishings

- New Fabric

- Clearance Fabric

- Pound Fabrics

From soft furnishings, office blinds, and school carpets to commercial doors, fire-retardant fabrics and materials are an absolute necessity in everyday living. What were originally interior fire hazards are now designed to improve fire safety in the home.

A fire retardant fabric’s sole purpose is to slow rather than fuel a fire’s spread, keeping your home and those in it safer.

For the technical bit: Fire retardant fabric (‘fire resistant fabric’, or ‘FR fabric’) is a material that meets certain fire safety standards set by law.

Some fabrics are naturally fire retardant, like natural fibre wool fabrics, for example, pass the domestic upholstery standards without further chemical treatment (more on this later). Otherwise, non-FR fabrics can be treated to make them fire-safe.

Fabrics can be chemically treated to provide the all-important fire retardancy. Fabrics are either sprayed or dipped in flame-resistant and retardant chemicals.

Chemically treated fabrics are rated fire-retardant down to the temperature and time it takes to burn.

Fire and flame retardant fabrics are self-extinguishing fabrics, when a flame reaches these materials, the fabric will actually slow the burning process, or resist the flames altogether.

The added fabric chemicals prevent oxygen from reaching the material layer. The chemicals create a physical barrier on the fabric’s surface, slowing the burning process.

Other fabrics might have flame-retardant materials physically woven into the fabric, therefore any washing and cleaning will not deplete the fabric’s fire retardancy.

Our collection of flame-retardant fabrics includes faux leather, cotton ticking stripe, outdoor PU, faux fur and more. There’s really no need to make any compromises when it comes to fire-retardant upholstery fabric. You can still find soft, luxurious, durable fabrics in our fabric range. Take a look at the fabrics product page and product specifications to check the “Fire Retardancy” field to check the rating.

Otherwise just from looking and feeling a material you sadly can’t tell if it’s fire retardant. It’s best to check before you buy for the fire-retardancy seal of approval or the rating of the material.

There’s a lot to consider when choosing upholstery fabrics, curtain fabrics or soft furnishing fabrics for your home. Fire safety is generally improved when consciously choosing fire retardant fabrics in home improvements. Fire retardant fabric regulations differ between commercial and domestic properties, here’s what you need to know.

Upholstery fabrics used within a domestic environment have to pass domestic upholstery standards, also known as BS5852, Source 0 + 1, or simply as ‘cigarette and match‘. If you’ve ever bought a sofa or armchair you might recall seeing large tags with green borders attached to it, declaring that the piece meets domestic standards.

The short answer is: no, not necessarily. However, you should give it serious consideration, and we strongly recommend it, but there is no agency or body in the UK that will force you to cover your own furniture in FR fabric. The safety advantages are obvious, but if cost is a paramount concern then you can usually save a few pounds per metre by buying a non-FR fabric.

If you’re sending furniture off to a professional upholsterer, however, and providing your own fabric, then any reputable tradesperson will likely insist that you choose a fire-retardant upholstery fabric. Your upholsterer may refuse to work with your choice if you can’t supply an FR certificate. Upholsterers can be as liable under the law as a retailer would be if they tried to sell you a piece of furniture that doesn’t meet safety standards, even if they’re only recovering it.

The domestic standard doesn’t cover all scenarios. If you’re using the fabric in a contract environment–offices, hotels, restaurants, bars, pubs, clubs, etc…–then the fabric has to pass to a higher contract upholstery standard. Known as BS5852, Source 5, or simply Crib 5 (named so for the equipment used to test the fabric in a laboratory–a small wooden crib).

This fabric will usually be more expensive, as a heavier application of FR chemicals is often required to bring a non-FR fabric up to standards.

There are actually no UK standards for fabric used in domestic curtains. If you were making curtains for yourself then arguably this makes little difference, as you could have chosen a non-FR curtain fabric anyway. This also means that you can make curtains for sale to the general public without having to worry about the safety requirements.

However, choosing fire-retardant fabric for curtains is a great way to introduce peace of mind into your nest and an attractive feature for buyers when purchasing your curtains (if you make and sell them)!

There are requirements for curtains used in a contract environment, and the British standard is known as BS5867 Part 2. There are many subtypes to the standard according to the environmental risk – an office, for example, is considered relatively low risk, whereas a hospital or prison would be considered a much higher risk.

The best advice we can offer when trying to get to grips with this standard would be to contact your local fire officer.

We don’t currently sell any fabrics that have been explicitly tested to the BS5867 standard. Some may, but you would need to have them tested yourself in order to confirm, and we offer no warranty or guarantee as to a particular result.

A common question. Aside from the obvious safety concerns, it depends on where the end product is being used.

If you’re making something yourself, for use in your own home, then there should be no other risks than the obvious safety implications. If you’re making products that you plan to sell, however, then you could be exposing yourself to both civil and criminal liability if the worst happens.

If you’re buying for a contract environment, then you’ll need to be able to supply proof that your upholstery and curtains meet UK standards if you’re ever inspected by your local fire office. How likely such an inspection is to happen will depend on the locality, but it shouldn’t be considered worth the risk.

Another common question. A fire retardant or resistant fabric isn’t fireproof fabric. It will still burn if you set fire to it. The aim of treatment, and the British standards in general, isn’t to stop the fabric from catching on fire, but rather to slow the spread of flames enough that it gives you and your family time to escape the property.

Keep your home and loved ones safe with fire-retardant fabric from Fabric Online. Find peace of mind in your next upholstery or soft-furnishings sewing project. Explore our collection of fire-retardant upholstery fabric, FR textiles and fire-retardant fabric for furniture and more with Fabric Online.

Award Winning Service

Award Winning Service

Customers who shop at Fabric Online benefit from our award winning and trusted customer service–every time.

Free Sample Swatches

Free Sample Swatches

Shop with absolute confidence by taking advantage of our free sample service for all fabrics and furnishings.

Free Delivery Over £150

Free Delivery Over £150

Save even more with free Mainland UK delivery on orders over £150. Conditions and restrictions may apply.

Our Story

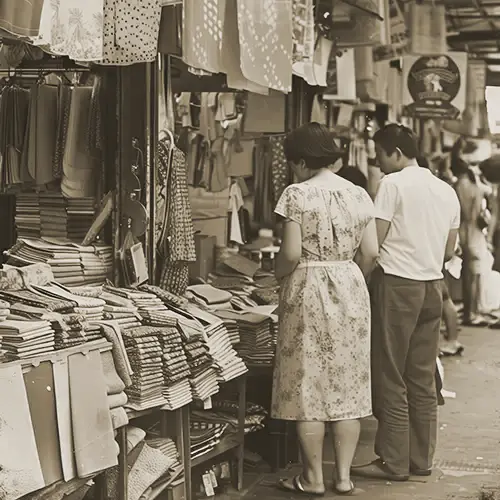

Our Story

From humble marketplace beginnings in Manchester to a nationwide online retailer and international wholesaler.

Trade Orders

Trade Orders

Trade customers looking to order larger or regular amounts of fabric should contact our dedicated wholesale team.

Clearance Fabric

Clearance Fabric

Unmissable, time-limited bargains on clearance and one-off fabrics, with up to 90% off RRP.